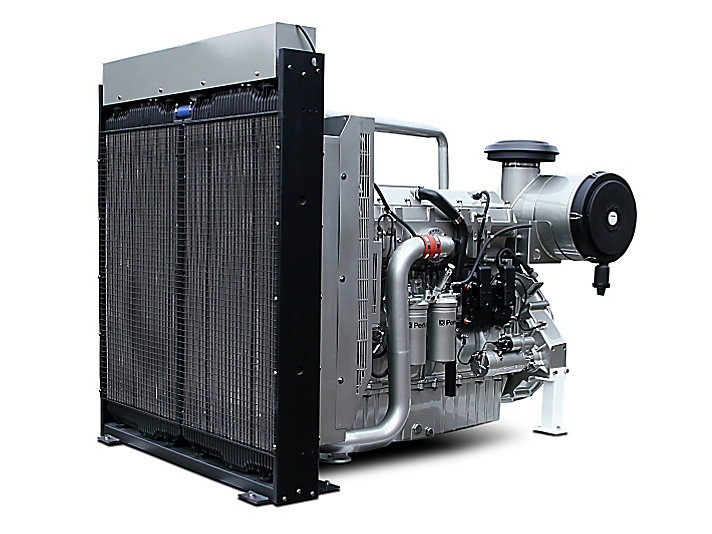

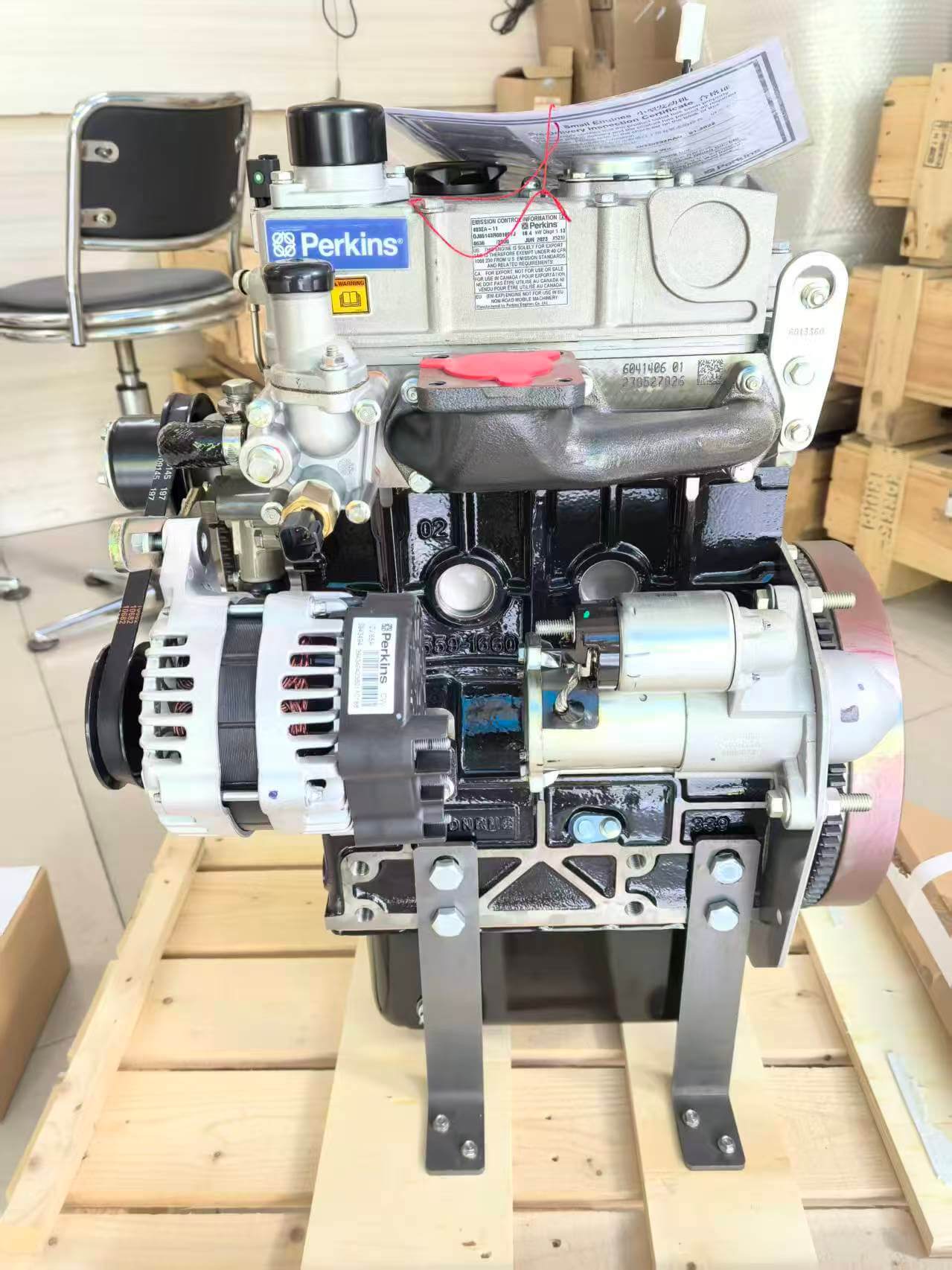

Perkins 2806A-E18TAG2 Diesel Engine For Generator SetsProduct Description

Perkins 2806A-E18TAG2 Diesel Engine For Sale – Product Overview

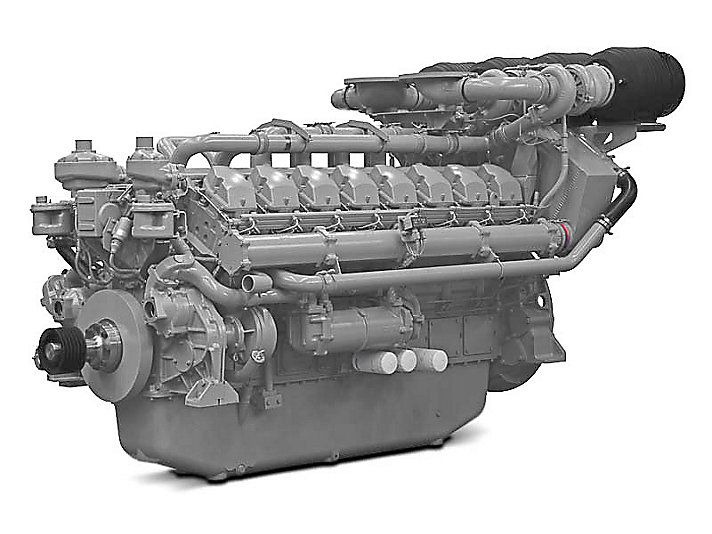

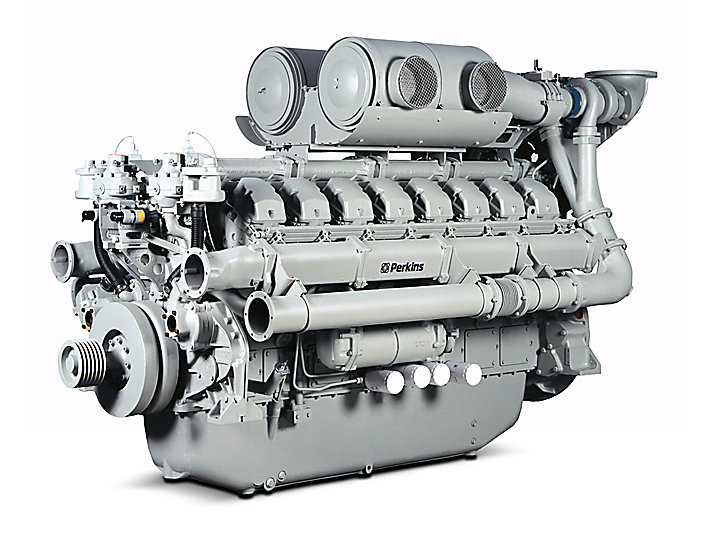

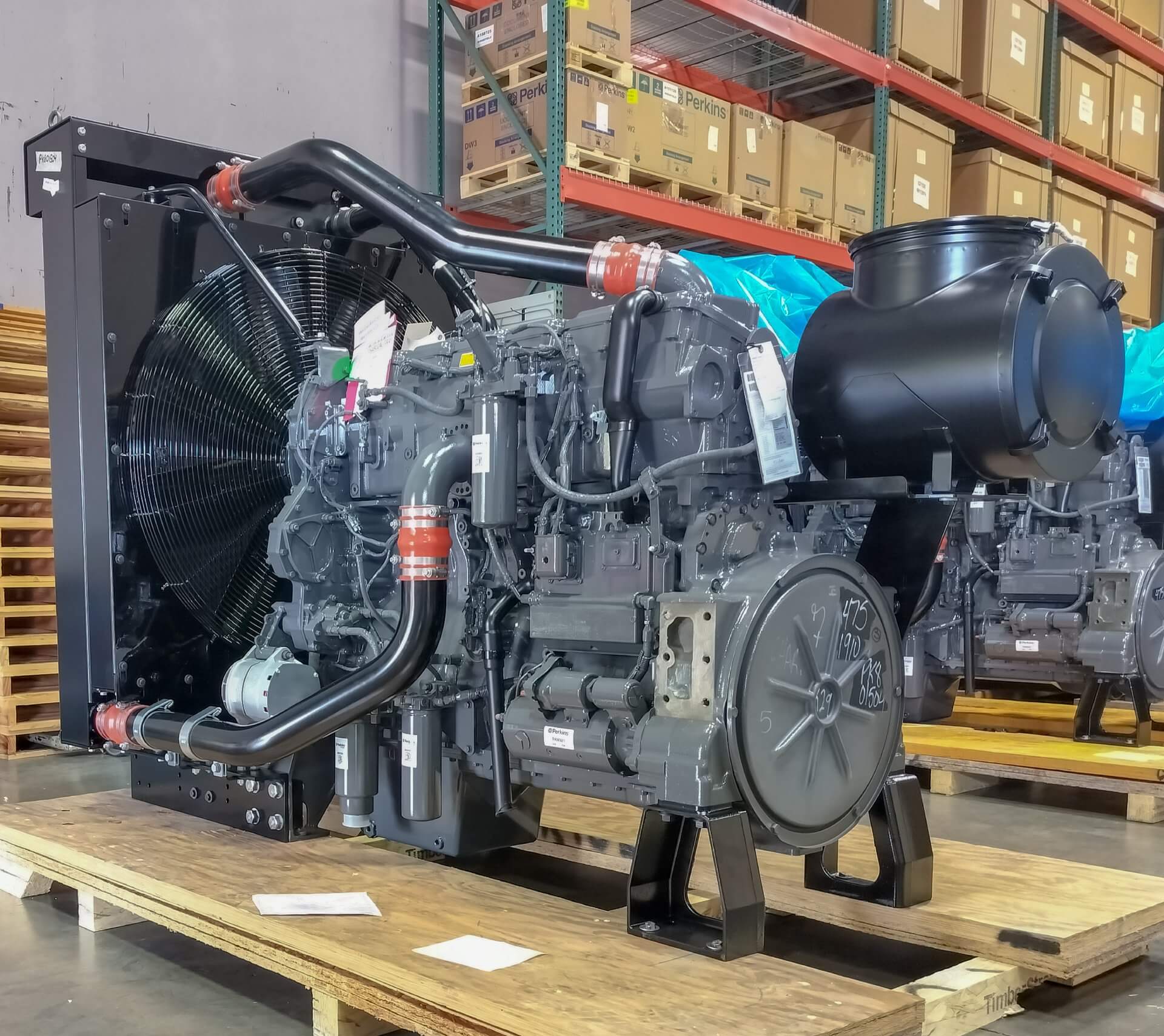

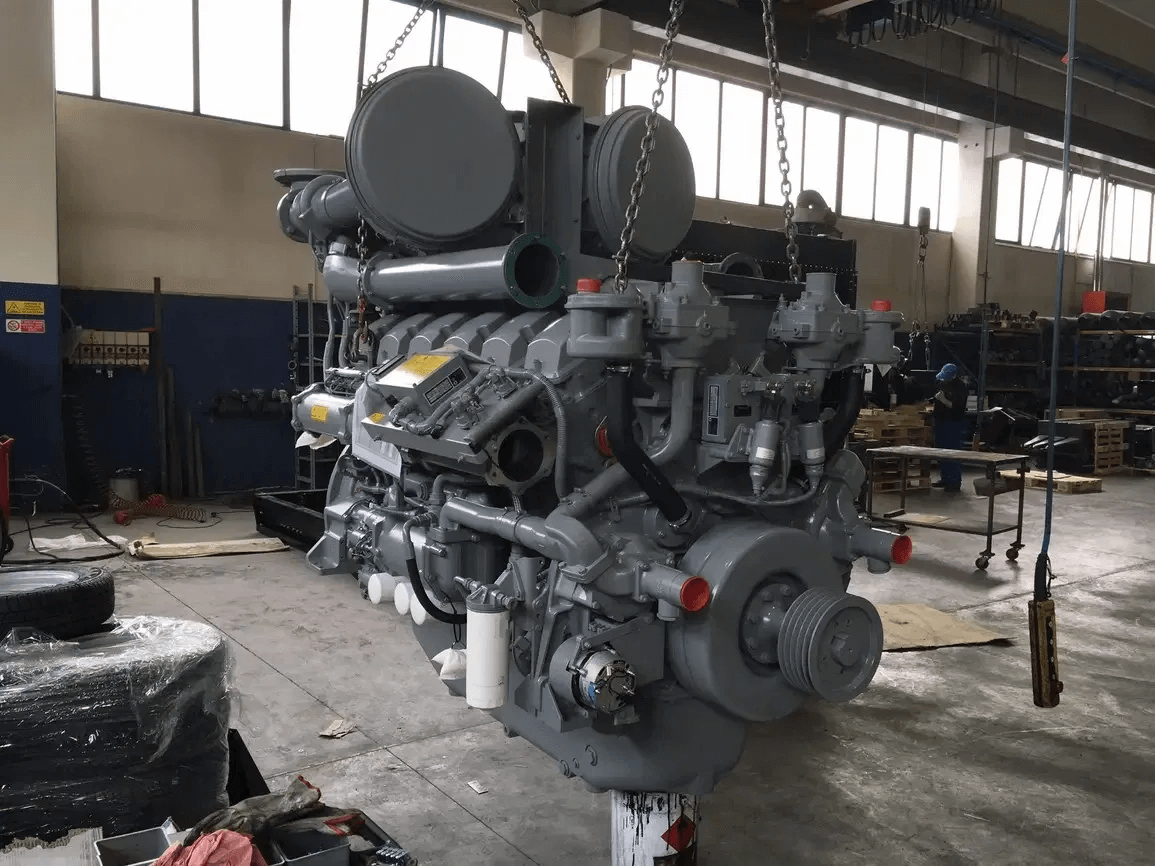

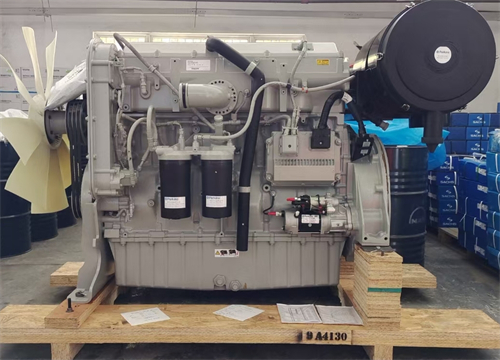

The Perkins 2806A-E18TAG2 is an 18L inline 6-cylinder diesel engine, featuring turbocharging and air-to-air aftercooling. It is specifically designed for medium to large industrial generator sets, delivering reliable performance in continuous-duty and high-load power generation applications.

Reliable Power for Continuous Operation

Operating at 1500 rpm, the Perkins 2806A-E18TAG2 provides a typical prime power output of around 500 kW. The engine is suitable for 24/7 continuous operation and allows 10% overload for 1 hour in every 12 hours, ensuring stable power supply for critical facilities such as factories, data centers, and infrastructure projects.

Efficient Fuel Consumption

Equipped with a Perkins electronic fuel injection system and a well-matched turbocharger, this 18-liter diesel engine delivers precise fuel control and stable combustion. Typical fuel consumption can be as low as 202 g/kWh, helping reduce long-term fuel costs and overall operating expenses for generator operators.

Emission Compliance

The 2806A-E18TAG2 complies with EU Stage III (Euro III) emission standards, making it suitable for industrial and overseas power projects where emission compliance is required.

Easy Maintenance & Global Support

With a compact engine layout and well-positioned service points, routine maintenance and parts replacement are straightforward. This design helps minimize downtime and simplifies on-site servicing. Backed by Perkins’ global service network, the engine offers dependable technical and after-sales support throughout its service life.

Built for Harsh Environments

Designed for demanding conditions, the Perkins 2806A-E18TAG2 operates reliably in high temperatures, high humidity, and corrosive environments. It is widely used in:

- Industrial standby and prime power generator sets

- Data centers and critical power infrastructure

- Energy, marine, and offshore-related applications

Not sure if this 2806A-E18TAG2 engine fits your machine? Send us your Engine Serial Number (ESN) — we will match it within 30 minutes.

Engine Application

Industrial Manufacturing & Data Centers

Generator sets powered by the Perkins 2806A-E18TAG2 diesel engine are widely used as standby or critical power in industrial manufacturing, especially for production lines with high power continuity requirements, such as automotive stamping, welding, painting, and assembly.

In the event of a grid outage, the generator set can start quickly and deliver stable power, helping reduce production downtime and equipment losses.

For data centers, the 2806A-E18TAG2 provides stable and continuous backup power for servers and core systems. With low vibration and controlled noise levels, it supports 24/7 continuous operation without affecting sensitive equipment.

Mining, Energy & Oil Fields

In mining and energy operations, the Perkins 2806A-E18TAG2 generator set supplies continuous power for mining equipment, crushing systems, and auxiliary facilities.

The engine performs reliably in high-temperature, dusty, remote, and off-grid environments, making it suitable for long-term use in remote mining areas.

In oil field applications, it provides dependable power for drilling, pumping, and oil processing systems, supporting both onshore and selected offshore operations while reducing the risk of power-related production interruptions.

Construction & Infrastructure

On construction sites, the Perkins 2806A-E18TAG2 generator set is commonly used as a temporary or mobile power source, supplying electricity for cranes, concrete equipment, site lighting, and construction elevators.

It is well suited for frequent start-stop and relocation, meeting phased and area-specific power demands. In infrastructure projects such as roads and bridges, the generator set supports key processes like concrete pouring and on-site facilities, helping keep projects on schedule.

ZEB Power collaborates with the authorized Perkins's Tier 1 dealer more than 15 years in China. We welcome enquiries for quotations and stock verification.Tell us your equipment model (Generators / Loader / Excavator / Underground Truck), we will recommend the correct configuration.

What is the fuel consumption of the Perkins 2806A-E18TAG2 diesel engine?

Fuel consumption of the Perkins 2806A-E18TAG2 diesel engine for generator sets varies depending on operating load. At 1500 rpm prime power, typical fuel consumption is as follows:

50% load: approximately 66 litres per hour

75% load: approximately 97 litres per hour

100% prime power: approximately 132 litres per hour

Standby power: approximately 143 litres per hour

These figures provide a practical reference for fuel planning and operating cost estimation in continuous and standby power generation applications.

Available Parts List

We maintain large stock for core components for fast shipment — injectors, pistons, rings, bearing, connecting rod, pumps, gaskets turbos, overhaul kits etc,. always ready.”

We supply Genuine and remanufactured options — tell us your budget, and we'll recommend the best choice.

Want to check Perkins 2806A E18TAG2 Parts manual? Contact us to get the latest availability list

| Item | Part Name | Part Number | Engine Model | Quality |

|---|---|---|---|---|

| 1 | MAIN BEARING KIT | KRP3122 | 2806A-E18TAG2 | Original Perkins |

| 2 | THRUST WASHER KIT | KRP3206 | 2806A-E18TAG2 | Original Perkins |

| 3 | VALVE COLLET | CH10019 | 2806A-E18TAG2 | Original Perkins |

| 4 | VALVE SPRING INNER | CH11489 | 2806A-E18TAG2 | Original Perkins |

| 5 | VALVE SPRING OUTER | CH11487 | 2806A-E18TAG2 | Original Perkins |

| 6 | VALVE GUIDE | CH10724 | 2806A-E18TAG2 | Original Perkins |

| 7 | EXHAUST VALVE | CH11022 | 2806A-E18TAG2 | Original Perkins |

| 8 | INTAKE VALVE | CH11021 | 2806A-E18TAG2 | Original Perkins |

| 9 | LINER - PRESS FIT | CH12742 | 2806A-E18TAG2 | Original Perkins |

| 10 | CON ROD ASSEMBLY | CH11507 | 2806A-E18TAG2 | Original Perkins |

| 11 | BIG END BEARING KIT | KRP3016 | 2806A-E18TAG2 | Original Perkins |

| 12 | PISTON RING KIT | KRP3015 | 2806A-E18TAG2 | Original Perkins |

| 13 | ENGINE CONTROL MODULE | CH12800R | 2806A-E18TAG2 | Original Perkins |

| 14 | STARTER MOTOR | CH11441 | 2806A-E18TAG2 | Original Perkins |

| 15 | BELT | CH11186 | 2806A-E18TAG2 | Original Perkins |

| 16 | OIL PUMP | CH10860 | 2806A-E18TAG2 | Original Perkins |

| 17 | OIL FILTER ASSEMBLY | KRP1719 | 2806A-E18TAG2 | Original Perkins |

| 18 | WATER PUMP KIT | KRP1678 | 2806A-E18TAG2 | Original Perkins |

| 19 | TURBOCHARGER | CH11516 | 2806A-E18TAG2 | Original Perkins |

| 20 | EXHAUST MANIFOLD | CH11556 | 2806A-E18TAG2 | Original Perkins |

| 21 | EXHAUST MANIFOLD | CH11557 | 2806A-E18TAG2 | Original Perkins |

Why Work With Us?

1.We offer 2 quality levels — Original and Remanufactured— allowing you to choose based on project budget.

2.We work with the authorized Perkins agent directly in China

3.Large real-time stock enables fast delivery for urgent mining jobs.

4.Technical team supports part matching & troubleshooting

5.We support long-term supply for distributors and mining projects.”

6.Serving mining clients in South America, Africa, CIS, Australia and Southeast Asia etc,.

Packaging & Shipping

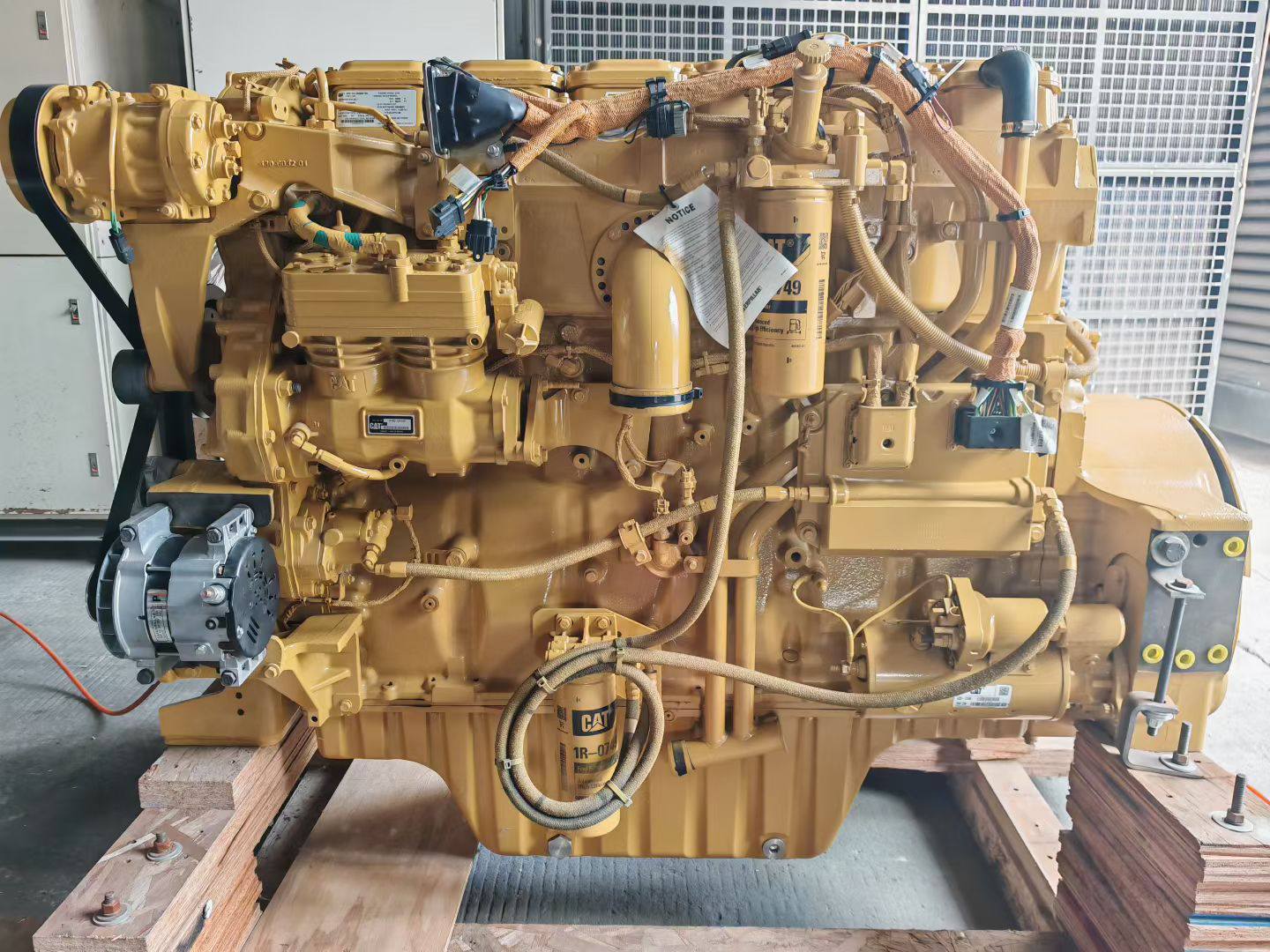

Each engine undergoes strict appearance and serial number inspection before shipment and is packaged in reinforced steel-framed wooden boxes with moisture-proof and orientation labels. Key components such as ECM and fuel injectors are packaged in independent shock-proof containers and are accompanied by export certificates.

We maintain long-term cooperation with international freight forwarders and offer trade terms such as CIF, FOB, and DDP according to customer requirements. Customers in Africa and Southeast Asia usually choose LCL or FCL shipping by sea, with an average delivery cycle of 18–25 days.

Perkins 2806A-E18TAG2 Diesel Engine For Generator SetsConfiguration

Perkins 2806A-E18TAG2 Technical Specifications

| TOTAL POWER RANGE | |

|---|---|

| Gross Mechanical Output | 540–678 kWm |

| Typical Electrical Output | 600–750 kVA (480–600 kWe) |

| Rated Speed | 1500 / 1800 rpm |

| EMISSION STANDARDS | |

| Emissions | Fuel Optimised |

| 50 Hz TYPICAL ELECTRICAL OUTPUT | |

| Prime | 600–650 kVA |

| Standby | 660–700 kVA |

| 60 Hz TYPICAL ELECTRICAL OUTPUT | |

| Prime | 500–545 kWe |

| Standby | 550–600 kWe |

| GENERAL | |

| Number of Cylinders | 6 vertical inline |

| Bore | 145 mm |

| Stroke | 183 mm |

| Displacement | 18.1 L |

| Compression Ratio | 14.5:1 |

| Aspiration | Parallel turbocharged, air-to-air charge cooled |

| Combustion System | Direct injection |

| Rotation (Flywheel End) | Anti-clockwise |

| Cooling System | Liquid |

| Aftertreatment | – |

| Typical Alternator Efficiency | 92% |

| Switchable | Yes |

| ELECTROPAK DIMENSIONS | |

| Length | 2545 mm |

| Width | 1536 mm |

| Height | 1808 mm |

| Dry Weight | 2050 kg |

| Disclaimer | Final dimensions dependent on selected options |