Perkins 2806D-E18TA and CAT C18: Powering the XCMG 950 Mining Excavator

The XCMG 950 mining excavator is widely used in large-scale mining and heavy earthmoving projects. Two well-recognized engines are commonly installed on this model: the Perkins 2806D-E18TA diesel engine and the Caterpillar C18 diesel engine.

These two engines are regarded as the “core power units” of the XCMG 950, providing the strength required for high-intensity mining operations.

This article takes a detailed look at the performance, technical features, real-world application results, and maintenance characteristics of both engines, offering a clear technical reference for mining equipment operators and project decision-makers.

1. Perkins 2806D-E18TA Engine Performance and Specifications

The Perkins 2806D-E18TA engine delivers a wide power output range, making it highly adaptable to different mining working conditions.

• Maximum power: up to 597 kW (approximately 800 HP)

• Minimum power: 429 kW (approximately 580 HP)

This broad power range allows mining equipment fitted with the 2806D-E18TA to handle both lighter earthmoving tasks and demanding mining excavation operations with sufficient power reserve.

In terms of torque performance, the engine provides:

• Maximum torque: 2043 lb-ft (approximately 2769 Nm) at 1400 rpm

The strong low-speed, high-torque characteristic enables excavators to perform efficiently during start-up, climbing, and hard material excavation. Stable torque output improves digging efficiency and overall operational productivity.

1.1. Technical Features of the Perkins 2806D-E18TA

The Perkins 2806D-E18TA incorporates several advanced technologies that contribute to its performance and efficiency.

The advanced electronic fuel injection system precisely controls fuel injection quantity and timing. This ensures more complete combustion inside the cylinders, improving power output while significantly enhancing fuel utilization. As a result, fuel consumption and exhaust emissions are reduced, lowering operating costs and improving environmental performance.

Another key feature is the turbocharging system, which increases intake air efficiency. By supplying more fresh air into the cylinders, fuel combustion becomes more complete, allowing the engine to maintain high efficiency under varying operating conditions.

In addition, the engine is equipped with a full electronic control system, functioning as an intelligent control center. It continuously monitors engine speed, temperature, pressure, and other critical parameters, automatically adjusting operating conditions to keep the engine running at its optimal state. This significantly improves engine reliability and operational stability.

1.2. Real-World Application and User Feedback – Perkins Engine

In real mining applications, the Perkins 2806D-E18TA has demonstrated strong performance on the XCMG 950 excavator.

When operating in mining environments with hard rock and complex geological conditions, the excavator benefits from the engine's strong power output, enabling efficient and continuous excavation work.

Stable and reliable engine operation reduces unplanned downtime, ensuring continuity of mining production.

According to user feedback, many operators have given high evaluations of the engine's power performance, fuel economy, and reliability. One mining operator stated that the excavator equipped with the Perkins 2806D-E18TA performs consistently even under harsh mining conditions, with lower fuel consumption compared to previous equipment and convenient maintenance supported by Perkins’ extensive service network.

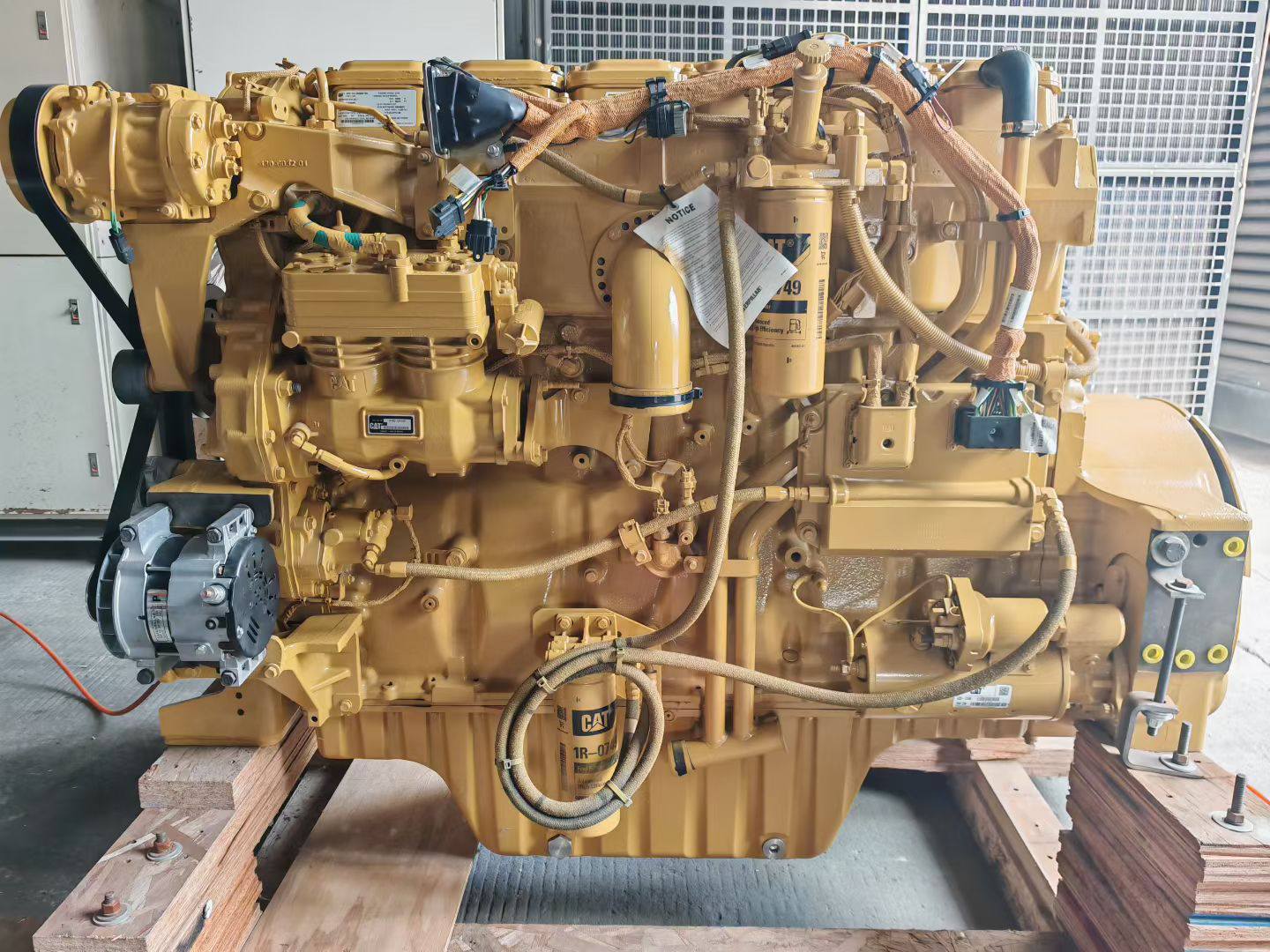

2. Caterpillar C18 Engine Performance and Technical Characteristics

The Caterpillar C18 engine is specifically designed to meet the demanding requirements of heavy construction and mining machinery.

• Configuration: inline six-cylinder diesel engine

• Displacement: 18 liters

• Maximum power: up to 597 kW (approximately 775 HP)

• Maximum torque: up to 3050 Nm

The high torque output available at relatively low engine speeds allows the excavator to perform more effectively during start-up, digging, and climbing operations, significantly improving work efficiency.

In terms of fuel economy, the C18 benefits from advanced fuel injection technology and optimized combustion processes, enabling efficient fuel utilization and reduced operating costs. Its durability and reliability allow long-term stable operation in harsh working environments, minimizing maintenance frequency and downtime.

2.1. Advanced Technologies of the Caterpillar C18

The Caterpillar C18 integrates several advanced technologies to achieve high performance and operational stability.

The Electronic Control Unit (ECU) continuously monitors engine operating parameters such as speed, temperature, and pressure. Based on this data, it precisely controls fuel injection quantity, injection timing, and air intake, ensuring optimal engine operation, improved power output, reduced fuel consumption, and lower exhaust emissions.

The common rail fuel system is another core technology. Fuel is pressurized by a high-pressure pump and stored in a common rail, then injected into each cylinder under ECU control. Compared to traditional systems, this allows higher injection pressure and more accurate fuel delivery, improving combustion efficiency and reducing pollutant emissions.

2.2. Application Results and Market Feedback – Caterpillar C18

In practical mining projects, the combination of the Caterpillar C18 engine and the XCMG 950 excavator has shown strong performance.

In large mining operations, the excavator can efficiently handle hard rock excavation, achieving higher hourly productivity compared to similar equipment.

Stable long-term operation under high-intensity workloads minimizes equipment failures and ensures smooth mining progress.

Market feedback indicates that users highly value the C18 engine’s power, durability, ease of maintenance, and dependable after-sales support.

3. Comparison Between the Two Engines

Performance Comparison

Both engines have similar displacement and power output levels, providing a solid foundation for heavy-duty mining work.

• The Perkins 2806D-E18TA offers slightly higher peak horsepower, providing additional power reserve under extreme conditions.

• The Caterpillar C18 delivers higher maximum torque, offering advantages in heavy digging and high-resistance operations.

Technology Comparison

• Perkins focuses on electronically controlled fuel injection and combustion optimization.

• Caterpillar emphasizes high-pressure common rail systems and advanced emission control technologies such as cooled EGR.

Cost and Maintenance

• The Caterpillar C18 may have a higher initial purchase cost due to brand value and advanced components.

• The Perkins engine offers convenient maintenance and strong global service coverage.

Both engines provide distinct advantages, and selection should be based on operating conditions, service availability, and long-term cost considerations.

Conclusion

Both the Perkins 2806D-E18TA and Caterpillar C18 engines demonstrate strong performance, advanced technology, and proven reliability when installed on the XCMG 950 mining excavator.

Their successful integration ensures efficient operation across a wide range of heavy mining and construction applications.

If you are evaluating engine options for mining excavators and require support with engine selection, configuration matching, and reliable supply, please visit our Contact Us page to discuss your project requirements with our technical team.