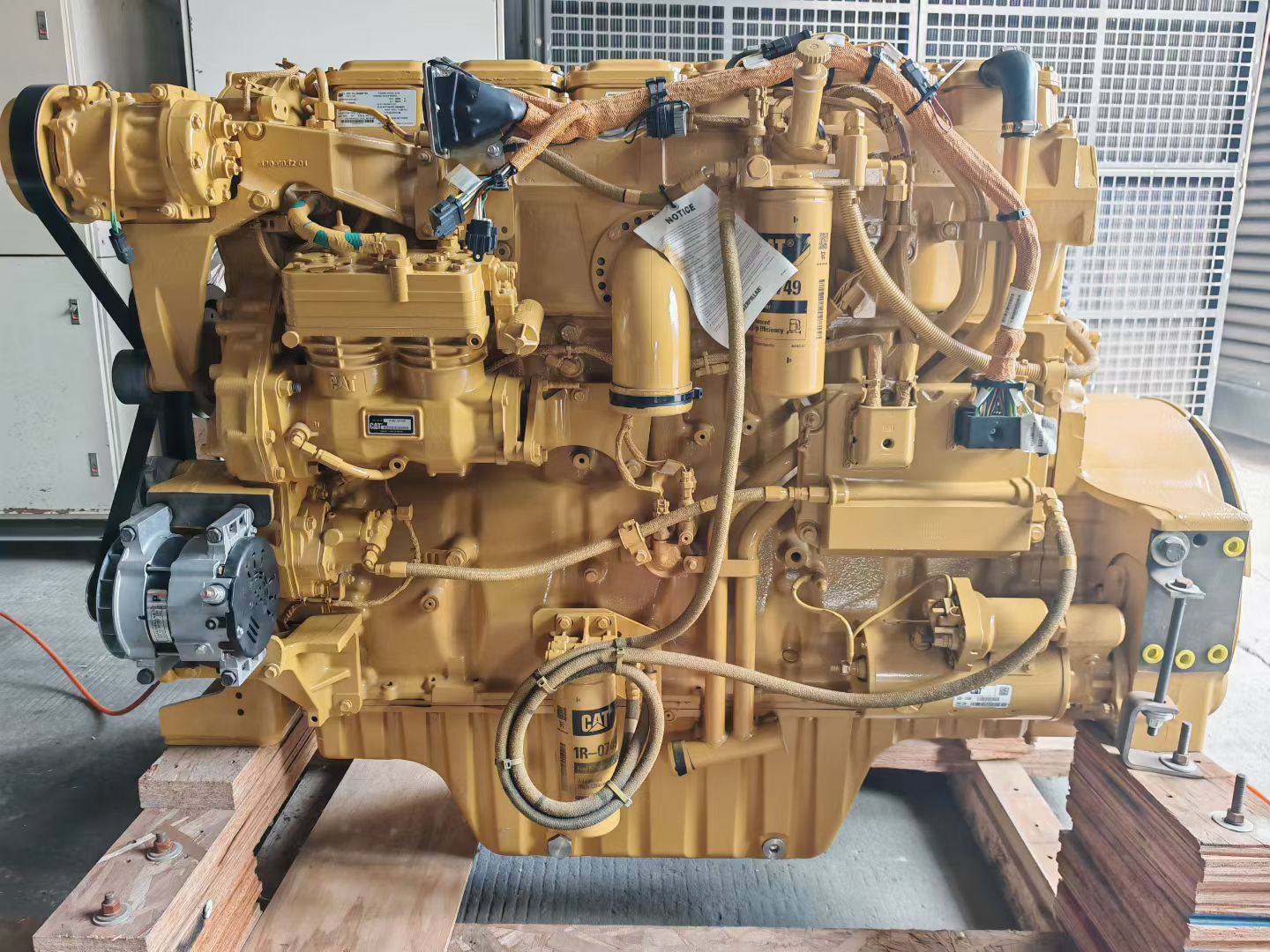

Diagnosing High Fuel Consumption in the Caterpillar C18 Engine

The Caterpillar C18 engine is known for its durability and strong performance in demanding industrial, construction, and marine applications. However, when fuel consumption becomes excessive, it often indicates underlying issues that require systematic inspection. Identifying these causes early helps operators keep the Caterpillar C18 engine running efficiently and economically.

1. Check Maintenance and Engine Condition

One of the most common reasons for high fuel consumption in the Caterpillar C18 engine is insufficient maintenance. Clogged filters, carbon buildup, or overdue oil changes can reduce combustion efficiency and increase fuel usage.Operators should inspect oil, water, and air filters regularly and replace them when necessary. Clean filters ensure proper airflow and fuel delivery, which directly affects efficiency.

Learn more about [Caterpillar C18 engine specifications]

2. Evaluate Fuel System Performance

The fuel system plays a crucial role in combustion efficiency. Inspect the fuel filters, injectors, and fuel pump to ensure there are no blockages or leaks. For precise diagnosis, use diagnostic tools such as CAT ET to read fault codes, perform injector solenoid tests, and conduct cylinder cut-off tests.

If any injector coil is not properly powered by the ECM, or if a cylinder misfires, the system should be repaired immediately. Regular inspection of the fuel injection system ensures that the Caterpillar C18 engine specs are maintained and fuel efficiency optimized.

Related product: [Caterpillar C18 engine for sale]

3. Inspect Air Intake and Exhaust Systems

Restricted airflow or exhaust leaks can lead to incomplete combustion and higher fuel consumption. Check the air intake system for leaks or blockage and ensure filters are clean. Use CAT ET to compare sensor readings between the intake and turbocharger outlet.

A well-functioning turbocharger ensures balanced air-to-fuel ratios, allowing the Caterpillar C18 marine engine to perform at full efficiency without wasting fuel.

4. Examine Auxiliary Equipment and Overload

Auxiliary equipment issues can also cause excessive fuel consumption. Check hydraulic attachments, pumps, or compressors for damage or overload. For instance, a malfunctioning breaker hammer or hydraulic motor can increase load, forcing the Caterpillar C18 engine to burn more fuel to maintain power output.

Repair or replace any damaged components to prevent unnecessary strain and maintain operating efficiency.

5. Monitor for Mechanical Wear and Damage

Mechanical wear, such as worn piston rings or leaking seals, can increase both oil and fuel consumption. Inspect for oil leaks around the crankshaft seal, valve cover gasket, or turbocharger oil lines.

A damaged turbocharger or diluted oil can also cause fuel inefficiency. Regular inspection and timely repair prevent further damage and keep your Caterpillar C18 engine running economically.

6. Comprehensive Diagnostic Approach

Diagnosing high fuel consumption requires a systematic inspection of the fuel, air, exhaust, and auxiliary systems. Using Caterpillar diagnostic tools, technicians can locate inefficiencies and resolve them before they escalate.By addressing these factors promptly, operators can extend the life of their Caterpillar C18 engine, reduce fuel costs, and maintain consistent power output—whether in mining, marine, or generator applications.

Need Expert Assistance?

If your Caterpillar C18 engine shows signs of high fuel consumption or performance loss, it’s time to seek professional help.

ZEB POWER provides accurate diagnostics, genuine replacement parts, and expert guidance for all Caterpillar C18 engine models.

Contact us today for a detailed inspection or quotation

ZEB POWER offers genuine Caterpillar C18 engine components and service support to keep your equipment performing efficiently and reliably in any environment.