Cummins Diesel Engines for Construction Machinery Markets

Cummins Diesel Engines for Construction Machinery Markets

Reliable Power for Global Equipment — Supplied by ZEB Power

Cummins is a global leader in construction machinery engines, offering the industry's widest power range from 2.8L to 15L and outputs from 46 to 600 horsepower.

Through both mechanical and full electronic control systems, Cummins engines achieve superior reliability, durability, fuel economy, and performance even in high-altitude or harsh environments.

Thanks to advanced turbocharging, preheating, and optimized combustion, these engines ensure low noise, high efficiency, and easy operation. Their compact design and simplified maintenance make them the preferred power source for OEM equipment worldwide. Cummins engines consistently deliver high uptime and exceptional return on investment, fully meeting the world’s toughest off-highway emission standards (Tier 4 / Tier 3).

Cummins engines power everything from compact excavators to large mining trucks—serving excavators, loaders, rollers, graders, pavers, air compressors, cranes, and forklifts with optimal performance.

Globally, Cummins partners with leading equipment manufacturers including Komatsu, Terex, Hyundai, Hitachi, Liebherr, LiuGong, Zoomlion, SANY, XCMG, and Lonking, providing deep experience across diverse industries and challenging operating conditions.

Cummins Engine Specifications for Construction Equipment

| Model | Displacement (L) | Cylinders | Power Range (HP) | Control Type | Emission |

|---|---|---|---|---|---|

| Cummins B3.3 / QSB3.3 | 3.3 | 4 | 60–110 | mechanical/electronic | Tier 2 / Tier 3 |

| Cummins B3.9 | 3.9 | 4 | 110–125 | mechanical | Tier 2 |

| Cummins B4.5 / QSB4.5 | 4.5 | 4 | 80–160 | mechanical/electronic | Tier 2 / Tier 3 |

| Cummins B5.9 | 5.9 | 6 | 150–178 | mechanical | Tier 2 |

Cummins B Series Engines — Compact, Efficient, and Field-Proven

Cummins B3.3 Small Diesel Engines

The Cummins B3.3 series is a compact diesel engine jointly developed by Cummins and Komatsu, available in mechanical and electronic versions with power outputs from 60 to 110 HP (45–82 kW). It meets Tier 3 / Stage IIIA emission standards for off-highway applications in Europe and North America.

It’s widely used in mini excavators, forklifts, generators, skid-steer loaders, air compressors, and aerial work platforms. Since its global launch, the B3.3 has earned a reputation for high reliability and low operating cost, becoming a favorite among construction equipment manufacturers.

In July 2008, the 100,000th unit rolled off the production line, representing over 600 million cumulative operating hours worldwide. Made in Japan, the Komatsu Cummins Engine Co. builds on the proven Komatsu D95 platform, continuously upgrading product technology and manufacturing processes.

Key Advantages:

• Proven global reliability — over 10 years of field experience

• High efficiency and strong performance up to 110 HP

• Low failure rate and reduced operating cost

• Low noise and eco-friendly design using rigid crankcase and vibration-isolated valve cover

• Direct injection system for fast starts and reduced emissions

• Compact structure, easy installation, and single-side maintenance

• Supported by Cummins’ worldwide aftersales network — 5,500 service locations in over 190 countries

Cummins B3.3 Series Small Diesel Engine Technical Specifications

| Model | Power (HP) | Torque (Newton Meter) | Air Intake Method | Emission |

|---|---|---|---|---|

| Cummins B3.3-85 | 85@2600RPM | 292@1600RPM | Turbocharging | Tier 3 |

| Cummins B3.3-85 | 85@2600RPM | 292@1600RPM | Turbocharging | Tier 2 |

| Cummins B3.3-80 | 80@2200RPM | 292@1600RPM | Turbocharging | Tier 3 |

| Cummins B3.3-80 | 80@2200RPM | 292@1600RPM | Turbocharging | Tier 2 |

Cummins B5.9 Diesel Engine

The Cummins B5.9 is one of the world’s most proven mid-range diesel engines, trusted by more than three million users globally. It features a one-piece cylinder block design that reduces component count by 40%, improving durability and reliability.

The B5.9 meets Tier 1 and Tier 2 off-highway emission standards, and when equipped with an air-to-air intercooler, it achieves even cleaner operation. Its balance of performance, cost-efficiency, and wide power range makes it one of Cummins’ most widely applied models in construction machinery.

Technical Overview:

• Displacement: 5.9 liters

• Cylinders: 6

• Power Range: 130–200 HP

• Control Type: Mechanical

• Emissions: Tier 1 / Tier 2 compliant

Applications:

Excavators, rollers, loaders, pavers, graders, forklifts, and airport ground-support vehicles (e.g., aircraft tractors, ground power units).

Key Strengths:

• Robust mechanical design with low failure rate

• Lower operating cost compared with competing engines

• Simplified maintenance and spare part availability

• Ideal for construction, agricultural, and utility applications

Technical Specifications of Cummins B Series 5.9L Small Diesel Engines

| Model | Power (HP) | Torque (Newton Meter) |

|---|---|---|

| Cummins B5.9-200 | 200@2500 | 804@1500 |

| Cummins B5.9-185 | 185@2500 | 746@1500 |

| Cummins B5.9-174 | 174@2500 | 621@1500 |

| Cummins B5.9-165 | 165@2500 | 597@1500 |

| Cummins B5.9-152 | 152@2500 | 561@1500 |

| Cummins B5.9-115 | 115@2200 | 424@1500 |

C Series Engines — High Output and Durability for Heavy Equipment

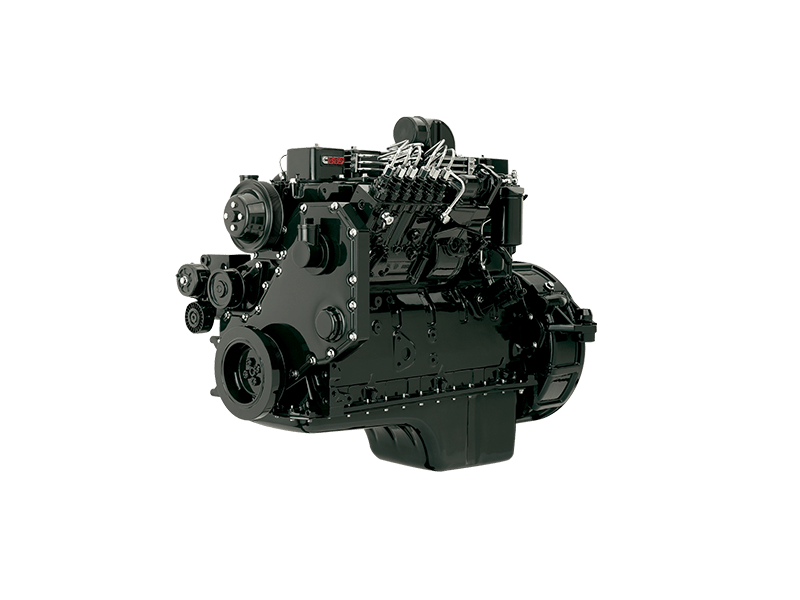

Cummins C8.3 Diesel Engine

The Cummins C8.3 engine powers a wide range of heavy-duty applications, including cranes, excavators, bulldozers, and agricultural machinery. With over one million units sold globally, the C8.3 series has demonstrated excellent endurance and dependability in even the harshest working environments.

Its inline fuel injection pump generates high injection pressure, ensuring clean combustion and enhanced fuel economy. The C8.3 meets Tier 1 / Tier 2 emission standards, and when fitted with an intercooler, achieves even cleaner exhaust performance.

Technical Overview:

• Model: C8.3

• Displacement: 8.3 liters

• Cylinders: 6

• Power Range: 185–260 HP

• Control Type: Mechanical

• Emissions: Tier 1 / Tier 2 compliant

Common Applications:

Loaders, graders, excavators, heavy rollers, pavers, concrete pumps, bulldozers, small milling machines, and airport ground equipment.

Key Advantages:

• High torque at low speeds

• Clean and efficient fuel combustion

• Exceptional reliability for long operating cycles

• Proven adaptability across mining, construction, and forestry applications

Technical Specifications of Cummins C Series 8.3L Small Diesel Engines

| Model | Power (HP) | Torque (Newton Meter) |

|---|---|---|

| Cummins C8.3-300 | 300@2200 | 1248@1600 |

| Cummins C8.3-260 | 275@2000 | 1119@1500 |

| Cummins C8.3-260 | 260@2200 | 1119@1500 |

| Cummins C8.3-240 | 255@2000 | 1017@1500 |

| Cummins C8.3-240 | 240@2200 | 1017@1500 |

| Cummins C8.3-230 | 230@2200 | 990@1500 |

| Cummins C8.3-215 | 215@2500 | 871@1500 |

| Cummins C8.3-205 | 205@2200 | 823@1500 |

| Cummins C8.3-190 | 200@2000 | 800@1500 |

| Cummins C8.3-190 | 190@2200 | 800@1500 |

L Series Engines — Designed for Wheel Loaders and Heavy Industrial Machinery

Cummins L9.3 Industrial Diesel Engine

The Cummins L9.3 industrial engine is developed from Cummins’ proven heavy-duty platform and optimized specifically for wheel loaders and heavy-duty industrial applications. Delivering up to 220 HP (162 kW), it meets China Stage II emission standards and can be upgraded to Stage III.

The L9.3 offers superior low-speed torque and a patented torque curve tailored for loader operation. Through optimized in-cylinder combustion and refined component design, it provides enhanced durability and improved fuel economy for demanding off-highway conditions.

Technical Overview:

• Model: L9.3

• Displacement: 9.3 liters

• Cylinders: 6

• Power Output: 220 HP (162 kW)

• Control Type: Mechanical

• Emissions: China Stage II (upgradeable to Stage III)

Key Advantages:

• Strong performance under heavy load

• Improved response and lower fuel consumption

• Long service life and reduced maintenance needs

• Perfect match for 5-ton loaders and similar heavy-duty applications

Technical Specifications of Cummins L Series 9.3L Small Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| 6L9.3T 220 | 220(162)@2200 | 890@1400 |

| 6L9.3T 220 | 220(162)@2200 | 980@1300 |

| 6L9.3TAA 220 | 220(162)@2200 | 940@1400 |

M Series Engines — Proven Power with High-Pressure PT Fuel System

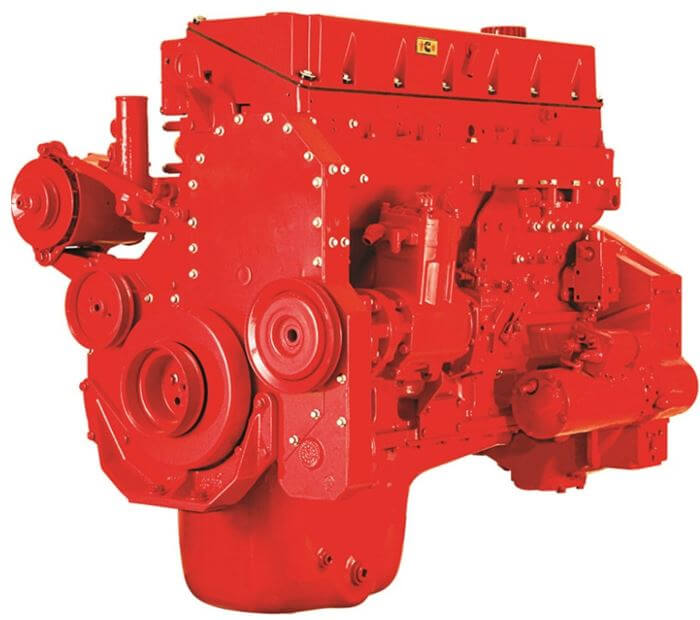

Cummins M11 Diesel Engine

The Cummins M11 engine utilizes Cummins’ patented PT (Pressure-Time) high-pressure fuel system, delivering exceptional atomization and efficient combustion.

By injecting fuel directly from the injector into the combustion chamber, the M11 achieves high injection pressure, improved fuel economy, and excellent cold-start performance.

With its simple design—no external high-pressure fuel lines—the M11 offers superior reliability and reduced maintenance. This engine meets Tier 1 off-highway emission standards and is widely used in heavy-duty equipment such as loaders, excavators, compactors, cranes, bulldozers, and air compressors.

Technical Overview:

• Model: M11

• Displacement: 11 liters

• Cylinders: 6

• Power Range: 280–350 HP

• Control Type: Mechanical

• Emissions: Tier 1 compliant

The M11 is available with CELECT and CENTRY electronic control systems, enhancing diagnostic capability, precision fuel delivery, and long-term operating stability in severe environments.

Technical Specifications of Cummins M Series M11 Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| M11-350 | 350@2100 | 1559@1300 |

| M11-335 | 335@1800 | 1458@1300 |

| M11-330 | 330@2100 | 1458@1300 |

| M11-320 | 320@2000 | 1234@1300 |

| M11-315 | 315@1800 | 1437@1300 |

| M11-310 | 310@2100 | 1424@1300 |

| M11-300 | 300@2100 | 1424@1300 |

| M11-290 | 290@2100 | 1329@1300 |

| M11-280 | 280@2100 | 1288@1300 |

| M11-275 | 275@1800 | 1288@1300 |

| M11-270 | 270@2100 | 1288@1300 |

| M11-270 | 270@1000 | 1248@1300 |

| M11-265 | 165@1700 | 1220@1300 |

| M11-250 | 250@2100 | 1146@1300 |

| M11-245 | 245@2100 | 1017@1300 |

| M11-245 | 245@2000 | 1058@1300 |

| M11-245 | 245@1800 | 1166@1300 |

| M11-225 | 225@2100 | 1031@1300 |

QSB Series — Intelligent Electronic Control, Low Noise, and Tier 3 Compliance

Cummins QSB3.3 / QSB4.5 / QSB6.7 Engines

The Cummins QSB series represents a new generation of electronically controlled, high-pressure common rail (HPCR) engines designed for compact to mid-size construction equipment.

The QSB3.3 (80–110 HP / 82 kW) inherits the reliability of the mechanical B3.3 while integrating full electronic control and HPCR fuel delivery, achieving performance levels comparable to 4.0L–4.5L engines—yet with 30% less weight and 3 dB lower noise.It meets Tier 3 off-highway emission standards and has won multiple awards, including Diesel of the Year (Europe) and Top 100 New Products (U.S. Construction Equipment Magazine).

The QSB4.5 (110–170 HP) and QSB6.7 (130–260 HP) are newly designed engines that replace earlier mechanical models (B3.9/B5.9).With optimized combustion and advanced ECM (twice the data processing speed), they achieve Tier 3 standards without using EGR, reducing maintenance and improving efficiency.

Design Highlights:

• Rear gear housing integrated with flywheel housing for reduced vibration and noise

• Mid-position injectors and symmetrical combustion bowl for cleaner burn

• Increased block rigidity and improved NVH (Noise, Vibration, Harshness) performance

Applications: Excavators, loaders, rollers, graders, and airport ground-support equipment (tow tractors, ground power units).

The QSB6.7 can be customized with torque curves specifically tailored for wheel loader operation.

Technical Specifications of Cummins QSB Series Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| QSB3.3 | 80@2200 | 372@1400 |

| QSB3.3 | 85@2600 | 372@1400 |

| QSB3.3 | 99@2200 | 412@1400 |

| QSB3.3 | 99@2600 | 412@1400 |

| QSB3.3 | 110@2400 | 412@1400 |

| QSB4.5 | 110@2200 | 489@1500 |

| QSB4.5 | 130@2300 | 511@1500 |

| QSB4.5 | 148@2300 | 598@1500 |

| QSB4.5 | 160@2200 | 622@1500 |

| QSB4.5 | 170@2500 | 622@1500 |

| QSB6.7 | 133@2000 | 431@1450 |

| QSB6.7 | 155@2200 | 618@1500 |

| QSB6.7 | 173@2200 | 800@1400 |

| QSB6.7 | 190@2200 | 929@1400 |

| QSB6.7 | 215@2200 | 888@1500 |

| QSB6.7 | 220@2200 | 945@1500 |

| QSB6.7 | 240@2500 | 987@1500 |

| QSB6.7 | 260@2500 | 990@1500 |

QSC Series — Clean Power for Heavy Construction and Industrial Applications

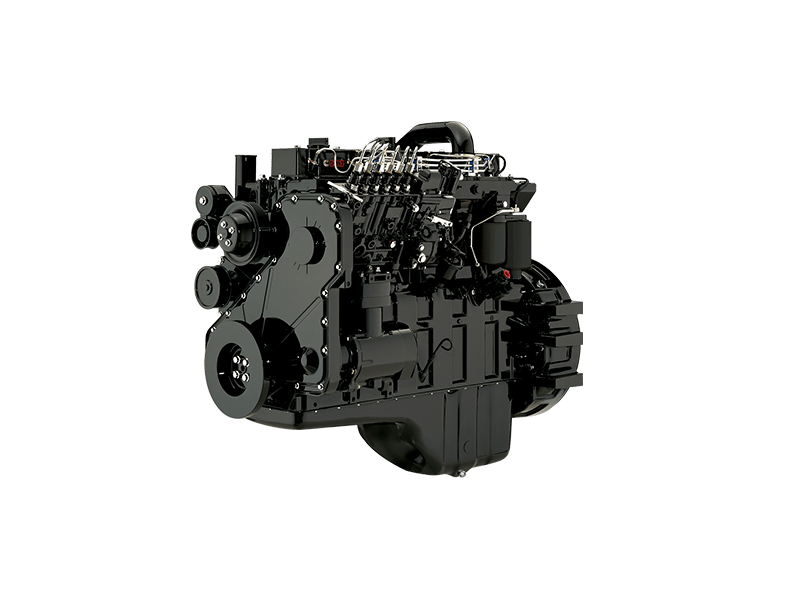

Cummins QSC8.3 Electronic Diesel Engine

The QSC engine series continues the legacy of the mechanical C8.3 while integrating full electronic control and high-pressure common rail fuel injection for superior performance.

The QSC adopts a 24-valve design, offering greater airflow, more complete combustion, and up to 50% noise reduction compared to the earlier C-series.

It delivers 240–340 HP and meets Tier 3 emission standards for off-highway equipment.

Key Benefits:

• Strong torque response at all RPM levels

• Enhanced throttle response via advanced ECM

• Clean, quiet, and fuel-efficient combustion

• Rugged cylinder block for high-load applications

Applications: Excavators, graders, cranes, and mining equipment operating in hot, dusty, or humid environments such as Australia, Southeast Asia, and Africa.

Technical Specifications of Cummins QSC8.3 Series Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| QSC8.3-340 | 340@2200 | 1424@1400 |

| QSC8.3-320 | 320@2200 | 1356@1400 |

| QSC8.3-300 | 300@2200 | 1356@1400 |

| QSC8.3-280 | 280@2200 | 1268@1400 |

| QSC8.3-260 | 260@2200 | 1178@1400 |

| QSC8.3-240 | 240@2200 | 1085@1400 |

QSM Series — Durable Power for Demanding Duty Cycles

Cummins QSM11 Electronic Diesel Engine

The QSM11 is one of Cummins’ flagship electronically controlled engines, the first globally to meet Tier 3 off-highway emission standards.

It uses Electronic Unit Injection (EUI) technology for precise fuel metering and complete combustion.

The high-capacity ECM is compact yet stores ten times more data than previous versions.

The forged-steel piston crown is heat-treated to withstand extreme cylinder temperatures, ensuring reliability under continuous heavy load.

Technical Overview:

• Model: QSM11

• Displacement: 11 liters

• Cylinders: 6

• Power Range: 290–400 HP

• Control Type: Fully Electronic

• Emissions: Tier 3 compliant

Applications: Mining loaders, dozers, large excavators, compressors, and heavy-duty industrial machinery.

Technical Specifications of Cummins QSM11 Series Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| QSM11-400 | 400@2100 | 1898@1400 |

| QSM11-375 | 375@2100 | 1898@1400 |

| QSM11-350 | 350@2100 | 1775@1400 |

| QSM11-335 | 335@2100 | 1673@1400 |

| QSM11-300 | 300@2100 | 1424@1400 |

| QSM11-290 | 290@2100 | 1478@1400 |

QSX Series — Advanced Dual Overhead Cam Design for Maximum Output

Cummins QSX15 Electronic Diesel Engine

The QSX15 is a next-generation, heavy-duty diesel engine designed for maximum power, torque, and emission compliance.

Featuring dual overhead camshafts and a patented Variable Geometry Turbocharger (VGT), the QSX15 optimizes air intake at both low and high RPMs for faster response and increased efficiency.

With power outputs from 375–600 HP, it meets Tier 3 off-highway standards and provides a strong platform for future Tier 4 compliance.

Its advanced combustion chamber design and heavy-duty cooling system make it ideal for extreme-duty applications in mining, agriculture, construction, and airport ground-support vehicles.

Technical Overview:

• Model: QSX15

• Displacement: 15 liters

• Cylinders: 6

• Power Range: 375–600 HP

• Control Type: Fully Electronic

• Emissions: Tier 3 compliant

Key Features:

• Dual overhead cam design for high torque output

• VGT turbocharger for variable power response

• Tier 4-ready combustion platform

• Exceptional durability in large-scale, continuous operations

Technical Specifications of Cummins QSX15 Series Diesel Engines

| Model | Power HP (KW) | Torque (Newton Meter) |

|---|---|---|

| QSX15-600 | 600@2100 | 2780@1400 |

| QSX15-600 | 600@1800 | 2780@1400 |

| QSX15-440 | 440@2000 | 2237@1300 |

| QSX15-425 | 425@2100 | 1949@1400 |

| QSX15-425 | 425@2100 | 1948@1400 |

| QSX15-375 | 375@2100 | 1871@1400 |

| QSX15-360 | 360@2100 | 1648@1400 |

Why Choose Cummins Engines from ZEB Power

For over 17 years, ZEB Power has been a trusted global supplier of genuine Cummins diesel engines and spare parts, specializing in high-performance solutions for construction, mining, agricultural, and industrial equipment.

We also provide replacement parts for Caterpillar, Perkins, and Cummins platforms—supporting OEMs and end users worldwide.

What Sets ZEB Power Apart:

• OEM-quality Cummins engines & components

• Global delivery to Australia, Southeast Asia, Latin America, and Africa

• Expert technical support for installation, matching, and maintenance

• Fast, reliable supply chain backed by Cummins’ worldwide service network (5,500 locations across 190+ countries)

ZEB Power helps clients achieve better uptime, lower fuel cost, and longer engine life, making it your trusted power partner for the world’s toughest environments.

________________________________________

Contact ZEB Power Today

Looking for reliable Cummins diesel engines for your construction, mining, or power generation equipment?

ZEB Power delivers fuel-efficient, emission-compliant, and durable engine solutions tailored for your region and equipment type.

Contact us today to discuss OEM Cummins engines or genuine spare parts for your fleet in Australia, Southeast Asia, Latin America, or Africa.

Let ZEB Power help you power success—wherever your equipment works.