Caterpillar C32 Daily Maintenance & Troubleshooting Guide

Caterpillar C32 Daily Maintenance & Troubleshooting Guide

(Mining, Power Generation & Data Center Applications)

The Caterpillar C32 engine is widely used in mining haul trucks, heavy-duty generator sets and mission-critical data centers. To maintain stable performance under harsh environments such as Australian mine sites, South American copper operations and Southeast Asian coal mines, routine maintenance is essential.This guide summarizes key C32 maintenance checkpoints, service intervals, and troubleshooting methods to keep your engine operating reliably.

1. Engine Oil & Oil Filter Maintenance

Engine oil is critical for lubrication, cooling and cleaning inside the Caterpillar C32 engine

Recommended Interval

Every ~500 hours, replace engine oil and oil filter.

Procedure

1. Shut down and cool the engine

2. Fully drain used oil

3. Remove and replace oil filter

4. Lightly oil the new filter seal

5. Refill with CAT-approved lubricant

6. Verify oil level using dipstick

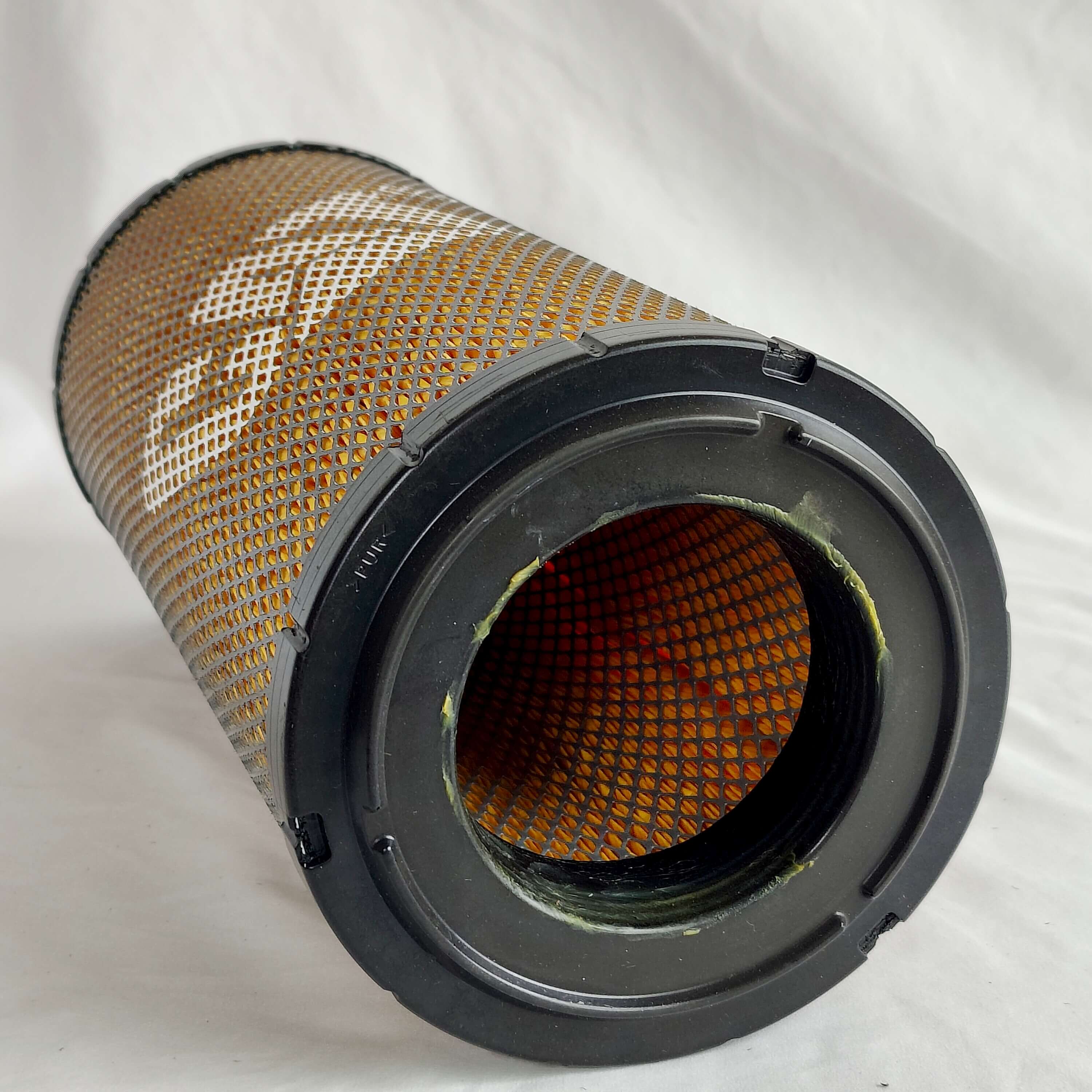

2. Air Filter Inspection & Replacement

A clean air filter ensures correct airflow for the C32 air intake system

Inspection Interval

Every 200–300 hours, more frequently in dusty mining environments.

Procedure

• Clean with compressed air (inside → outside)

• Replace if heavily clogged, damaged or oil-contaminated

3. Fuel System Maintenance

Proper maintenance of the C32 fuel system.ensures stable combustion and injector performance.

Recommended Interval

Replace fuel filter every 300–500 hours.

Checklist

• Close valve → replace fuel filter

• Inspect fuel lines for cracks or leaks

• Drain water separator

• Use clean diesel fuel meeting CAT specification

4. Common C32 Troubleshooting Guide

This section covers high-frequency failures in C32 maintenance

including starting issues, power loss and abnormal noises.

4.1 Hard Starting

Possible causes:

• Insufficient fuel supply

• Blocked fuel lines

• Clogged fuel filter

• Air trapped in the fuel system

• Weak or contaminated injectors

Corrective actions include replacing the filter, cleaning injectors and verifying pump pressure.

4.2 Low Engine Power

Common sources:

① Compression Loss

Wear on piston rings or cylinder liners.

② Fuel Supply Issues

Clogged filter, weak pump, injector malfunction.

③ Boost Pressure Problems

A faulty or inefficient C32 turbocharger will reduce intake airflow and engine output.

4.3 Abnormal Engine Noise

Ticking noise

Likely excessive valve clearance → adjust to spec.

Thudding noise

Possible connecting rod bearing wear → inspect & replace.

Crankcase noise

Potential crankshaft wear or seal failure → internal inspection required.

5. Why Proper C32 Maintenance Matters

For mining operations:

• Reduced downtime

• Longer component lifespan

• More stable turbocharger performance

• Better fuel efficiency under load

For data centers:

• Reliable backup power

• Faster start-up

• Thermal stability under sudden load shifts

6. How We Support Your C32 Fleet

We provide engineering-level support for mining and data-center operations, including:

• Oil, air and fuel filtration parts

• Injector and fuel-pump components

• C32 turbocharger assemblies & overhaul kits

• Cross-reference assistance

• Stable supply for high-hour fleets

Need support for your Caterpillar C32 engine?

If your mining or power-gen team requires parts, technical inspection guidance or maintenance planning, you can reach out anytime.

Contact Us